Training objectives

Benefits from training

Training description

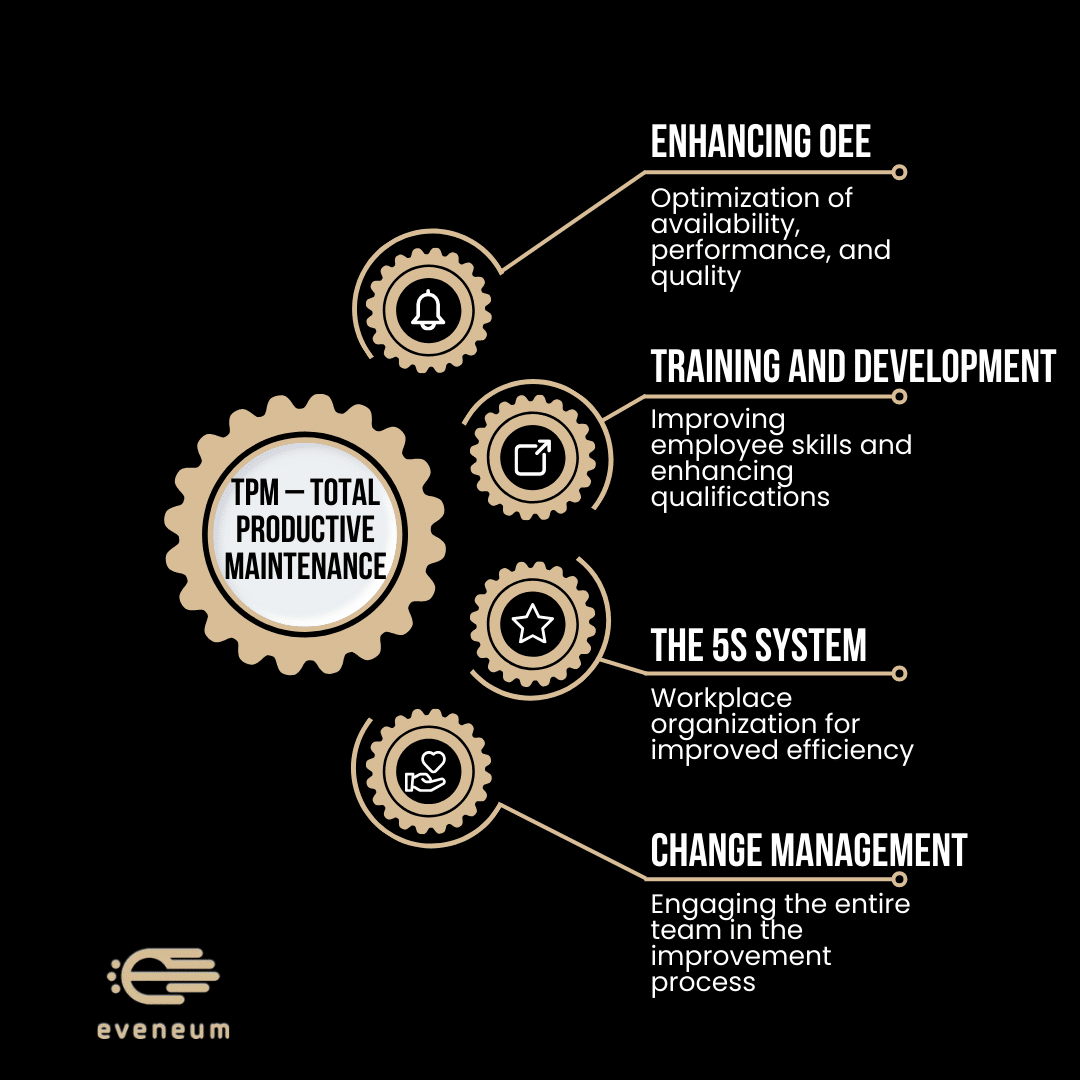

Increase production efficiency and minimize downtime with the TPM method – guaranteed time and cost savings!

In the face of the economic race between manufacturing companies, maintaining machines and equipment in excellent technical condition is crucial to ensure productivity, cost efficiency, and a competitive advantage. This training program will help your organization implement world- class machine maintenance standards – TPM, ensuring the highest quality machine maintenance and the necessary changes in production teams, maintenance departments, and management that will enable you to win this race.

During the training, participants will become familiar with the pillars of TPM, such as the 5S methodology, production loss analysis, and OEE (Overall Equipment Effectiveness), and will learn how to effectively implement these tools in their organization.

The program also covers change management aspects, engaging production teams and management in the TPM process. Additionally, participants will have the opportunity to participate in practical workshops on the production floor, where they will adapt the TPM methodology to the specific needs and challenges of their company.

The training is offered in two versions:

- For a single company on its premises, with the possibility of individual workshops on the production floor with selected machines, or

- In the form of general workshops outside the company for representatives of various enterprises.

Framework of training

- Introduction to TPM – Definition and Goals

- History of TPM Worldwide and in Poland

- The 8 Pillars of TPM

- The 5S Methodology and Its Role in TPM

- OEE Indicator – Practical Application

- Production Loss Analysis

- Managing Breakdowns and Downtime

- Tools Supporting TPM

- Employee Involvement in TPM

- Change Management in the Organization

- Practical Workshops on Machines

- Optimization of Production Processes

- Diagnosis of Maintenance Issues

- Continuous Improvement in the Company

- Challenges in Implementing TPM

- Software Supporting TPM

- Summary and Conclusions from Implementation

Trainer

Konrad Zimmer

Lean manufacturing and automation expert

A leader of industrial teams with over 20 years of experience, mainly in the automotive industry. He has worked as a production manager, maintenance manager, technical manager, and currently holds the position of plant director. A passionate advocate for technology, automation, digitization, and everything related to Lean Manufacturing, maintenance, TPM, and the manufacturing industry. He gained extensive experience in manufacturing companies such as Valeo in Poland and abroad, and Rolls-Royce, in areas such as production management, implementation of new products, processes, and machines, process optimization, maintenance management, and supplier quality management. A graduate of the AGH University of Science and Technology in Kraków with a degree in Automation and Metrology, as well as postgraduate studies in production management at WSZiB in Kraków.

Advanced Total Productive Maintenance – TPM

Duration: 16 hours

Start time: 9:00 am

Training venue:

The final location will be adjusted to the participants needs