Training objectives

Benefits from training

Training description

Lean Manufacturing – optimize processes, reduce costs, achieve excellence in production!

Are you wondering how to improve efficiency in your manufacturing facility? Unsure where to start the improvement process? Or perhaps you’re questioning whether investing in automation for production processes is worthwhile and when to implement it? Our training program "Lean Manufacturing – Fundamentals" will help you find answers to these questions and implement effective solutions in your company.

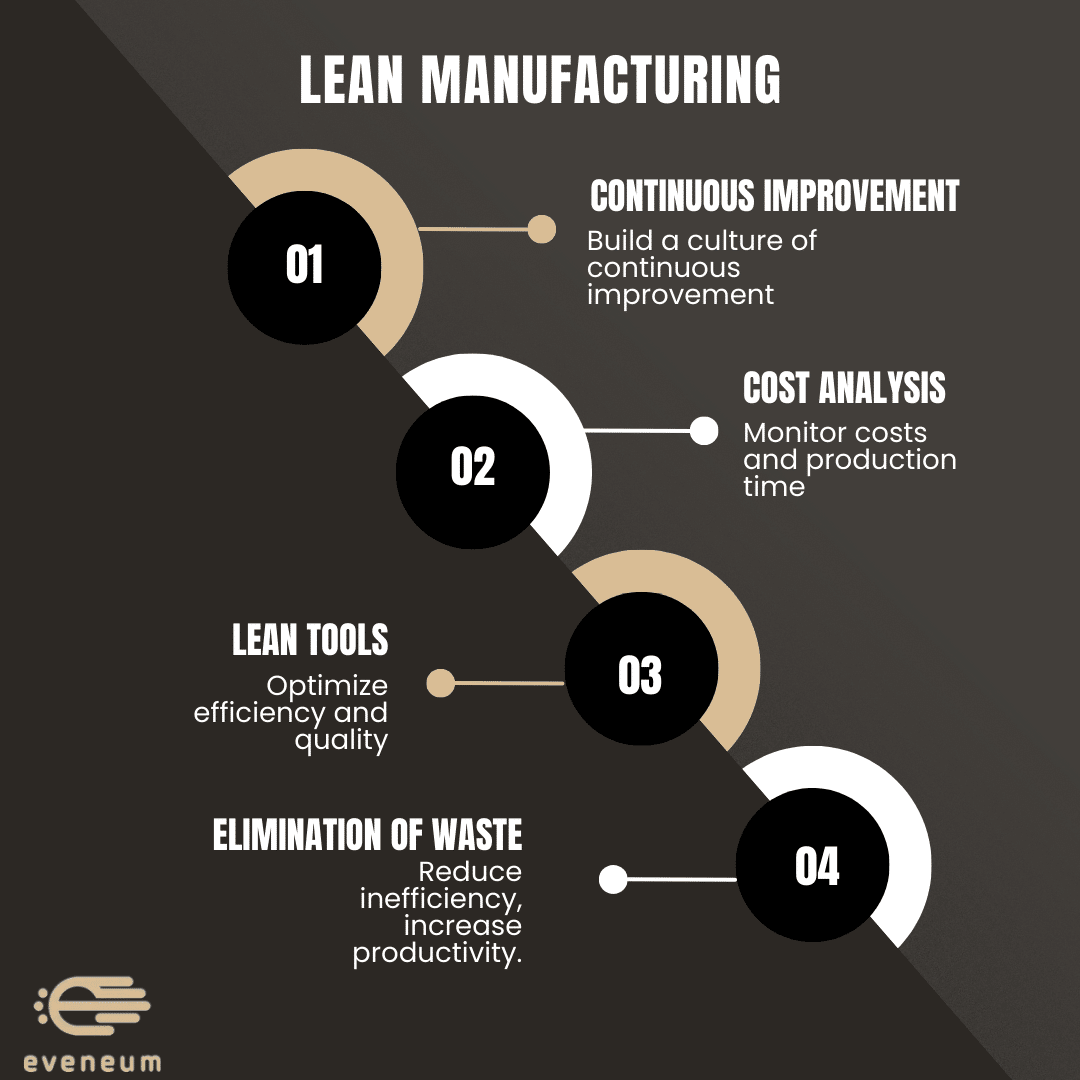

The "Lean Manufacturing – Fundamentals" training is a comprehensive introduction to the methodology that has been optimizing production processes in leading industrial plants for years. Learn how to efficiently manage production, eliminate waste, and optimize processes. You will understand how to use Lean tools to improve performance and quality, as well as how to introduce automation in response to rising labor costs.

During the training, participants will have the opportunity to work on a production simulation, taking on various roles (logistics, production, quality), implementing improvements, and analyzing real factors such as costs, production time, and machine failures. This practical approach will help build a more efficient manufacturing plant and teach how to engage the team in the process of continuous improvement.

The training is offered in two versions:

- For a single company on its premises, with the possibility of individual workshops on the production floor, or

- In the form of general workshops outside the company for representatives from various enterprises.

Framework of training

- Introduction to Lean Manufacturing

- Key Lean tools

- Waste analysis

- Production process management

- Value Stream Mapping (VSM)

- 5S in practice

- SMED (Single-Minute Exchange of Die)

- Root Cause Analysis

- Production costs

- Optimization of material and information flow

- Work standardization

- Advanced performance indicators (OEE, TMP, UR)

- Employee engagement in Lean processes

- Automation of production processes

- Production simulation

Trainer

Konrad Zimmer

Lean manufacturing and automation expert

A leader of industrial teams with over 20 years of experience, mainly in the automotive industry. He has worked as a production manager, maintenance manager, technical manager, and currently holds the position of plant director. A passionate advocate for technology, automation, digitization, and everything related to Lean Manufacturing, maintenance, TPM, and the manufacturing industry. He gained extensive experience in manufacturing companies such as Valeo in Poland and abroad, and Rolls-Royce, in areas such as production management, implementation of new products, processes, and machines, process optimization, maintenance management, and supplier quality management. A graduate of the AGH University of Science and Technology in Kraków with a degree in Automation and Metrology, as well as postgraduate studies in production management at WSZiB in Kraków.

Lean Manufacturing – basics – the path to efficient and economical production

Duration: 16 hours

Start time: 09:00 am

Training venue:

The final location will be adjusted to the participants needs