Author:

Increasing savings and reducing complexity in standard, catalogue components porftolio (so called c-class). A case study.

Industry: railway

Project goal: process improvement and savings

Areas: logistics, procurement, finance, production, R&D

Duration: two weeks

Number of people in the project: 5

Estimated project results

Why are standard parts a challenge and not a source of savings for manufacturing companies?

As part of the Why Purchasing? initiative, we spoke with Paweł Kudzia from Woodward company. He emphasized the challenges of generating savings faced by companies that have an extensive supply chain. Many suppliers provide components that are ultimately assembled in production. He described his supply chain as "low volume - high mix". You can watch the entire recording in the accompanying video.

How does this relate to our case study?

We often encounter the situation described by Paweł among our clients. Companies that are OEMs or are positioned high in the value chain are often characterized by the immortal Pareto principle:

-

20% of the purchased expensive components account for 80% of the material costs and savings.

However, what strikes us the most is another proportion:

-

80% of the process costs and troubles are generated by components with relatively low prices but complex logistics and supplied by a large number of suppliers. In other words, the remaining 80% from Pareto.

The Pareto principle doesn't work in tail spent management. Solutions are needed that fundamentally change the way we operate to document attractive savings. Today, modern Industry 4.0 technology comes to our aid. It allows us to network devices distributed throughout the production facility with the supplier system.

We had to face precisely such a situation with a client in the railway industry (nowadays often referred to as Mobility).

What do market trends say?

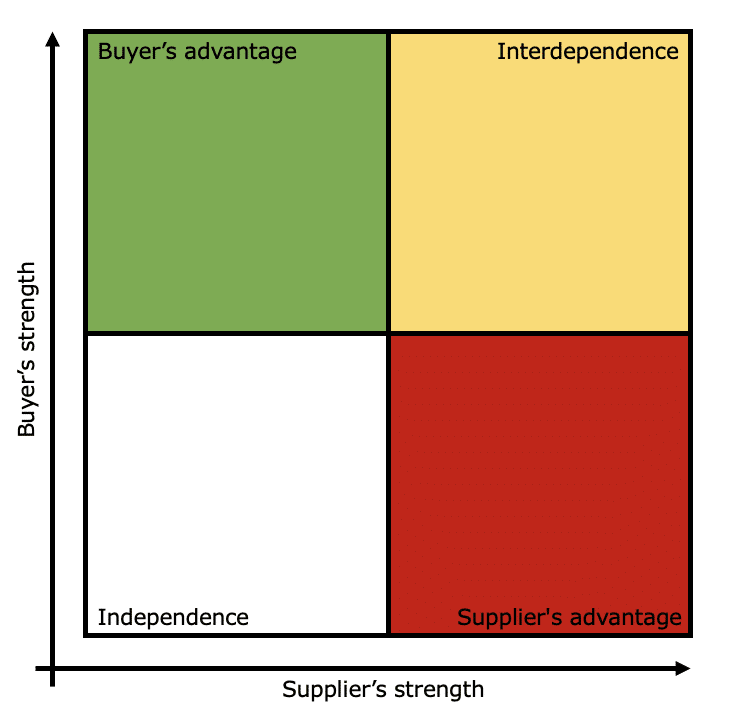

According to the latest purchasing trends, C-class components are classified as "outsourcing due to capabilities", especially in the low volume-high mix situation, based on the power balance matrix. It is assumed that for this type of component, a company wishing to focus on its core business should consider and implement lean solutions. These solutions are based on a service that has key efficiency indicators such as availability, flexibility, autonomy, and savings. The support provided by the supplier is intended to ensure flexible implementation of the core business for the customer. Current and future trends in C-class management indicate a shift from purchasing components towards purchasing a service related to component availability at an optimal cost.

Details of the case study in a company from the railway/mobility industry

Accounting and controlling

Identified challenges:

- Manual and time-consuming invoice processing.

- Nearly 15,000 invoices per month.

- 13,000 invoices represent the actual capacity of a 7-person department.

- An average of 2,100 invoices per person per month (100 invoices per day!).

- Overtime and backlogs up to one week in invoice entry.

- Late payments to suppliers result in a backlog of firefighting in purchasing, controlling, and accounting departments.

Proposed solutions:

- Standardizing invoicing terms in monthly cycles.

- Rapidly increasing the percentage of electronic invoices from 12% to 80%.

- Enforcing the requirement for suppliers to include order numbers and customer index numbers on invoices.

- Improving the electronic document workflow for resolving discrepancies.

- Introducing the "noPO, no Pay" indicator to increase purchasing transparency.

Production

Identified challenges:

- Production documentation is not always updated in a timely manner compared to the actual execution of a particular component. Planners order components that are not needed and fail to order the necessary ones.

- Some assembly sockets contain a large number of excess and unused components.

- Team leaders spend up to 2 hours per day searching for components needed for production.

- The existing ERP system does not track the visibility of components and their inventory after they are issued from the warehouse.

- Inventory policy is not effectively enforced, and "excess" components are often not returned to the warehouse.

- The warehouse frequently issues fewer components than what is required by the production demand.

Proposed solutions:

- Hiring a specialized company to map the streams of C-class parts in production.

- Implementing a modern kanban system based on IoT and remote communication with the supplier's cloud, in line with Industry 4.0 principles.

- Conducting a deeper analysis of the change process in specifications, involving design engineers, new launch engineers, and assemblers, to ensure the proper ordering of components for subsequent vehicle builds within a series and to capture and eliminate knowledge gaps.

- Conducting a deeper analysis of errors and their root causes in the demand-reservation-issuance-receipt process to eliminate shortages and downtime.

Logistics and purchases

Identified challenges:

- The procurement department processes nearly 70,000 orders annually for verified C-class components.

- This constitutes 70% of all processed orders.

- Lack of specialization among buyers, as they are responsible for the entire end-to-end logistics and procurement process.

- Each buyer handles approximately 30 orders per day, consisting of an average of 10 lines/items. Creating an order in the system takes around 5 minutes.

- Each order goes through an approval process according to the delegation of authority policy.

- The entire organization collectively spends approximately 30 minutes on each order.

- Buyers spend around 3-4 hours per day handling order-related tasks.

Proposed solutions:

- Outsourcing the handling of C-class components to minimize administrative work for buyers.

- Implementing a solution that allows real-time analysis of inventory levels, consumption, component locations, and trends based on historical usage.

- The recommended solution by Eveneum should free up resources by approximately 4.5 hours per day (3 hours of unproductive work on orders and 1.5 hours on invoices).

- We recommend allocating the freed-up resources to purchasing category management, contract optimization, or establishing an advanced early project planning team.

- Developing a set of key performance indicators and implementing goal-driven management in the procurement organization in response to the company's needs and strategy.

Szymon Tochowicz

Head of procurement, aerospace engineer

Head of procurement, aerospace engineer with 20 years in strategic sourcing. Managed teams of strategic buyers and category managers at the regional and global levels. Responsible for the project “Why Purchasing?” promoting procurement as a function. In Eveneum he is involved in consulting projects and customized trainings. He is specialized in automotive, aerospace, defense and energy industries. Trainer at the European Institute of Purchasing Management and lecturer at the Jagiellonian University.